PTFE RELEASE AGENTS |

|||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||

|

Miller-Stephenson PTFE Release Agents and Dry Lubricants offer high quality, value and purity. In this day of dynamic product development, Miller-Stephenson has remained consistent, providing alternatives which meet today’s rapidly changing needs while maintaining a bridge to formulations of the past. During this multi-decade transition from chlorofluorocarbon carriers to friendlier ozone-impact solutions, Miller-Stephenson continues to provide its customers with a wide selection of alternative products in both aerosol and bulk liquid form. We offer the best products currently available and continue to remain focused on the future. Meanwhile, we shall not lose sight of our never-ending objective of providing our customers with the quality products and services they have come to expect. PTFE - The MainstayPTFE (Polytetrafluoroethylene) has been the active ingredient in our Release Agent/Dry Lubricant formulations for many years. Except for manufacturing adjustments involving ozone friendly processes, PTFE has remained virtually the same and continues to be the premier release agent solution. The PTFE, in Miller- Stephenson formulations, provides suspensions of low molecular weight fluoropolymers in a variety of easy to use forms. PTFE’s outstanding lubricity and low coefficient of friction make Miller-Stephenson products not only ideal for mold release applications but also for dry lubrication.

Why Miller-Stephenson?Our products, with PTFE, provide distinct advantages not available from other formulations.

| |||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

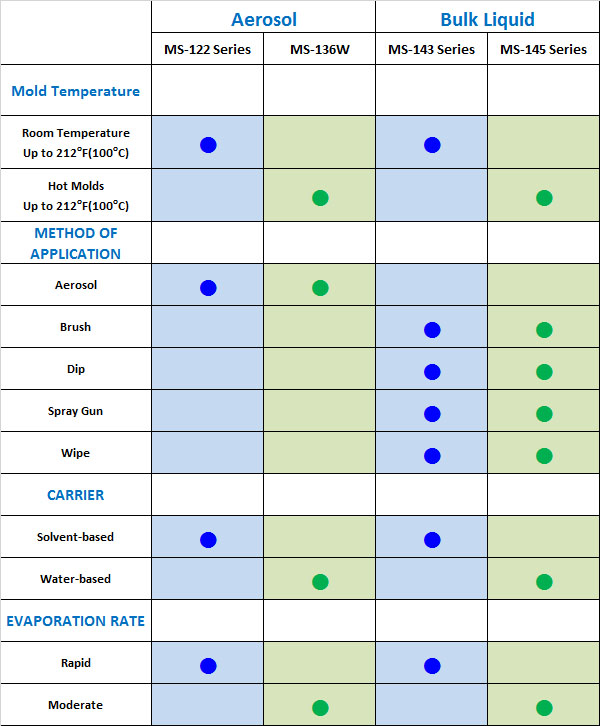

ROOM TEMPERATURE MOLDS: Apply MS-122 Series or 143 Series release agents on molds up to 212°F/100°C. Molds can then be heated to 580°F/304°C. HOT MOLDS: Apply MS-136W or MS-145W on pre-heated molds above 212°F/100°C up to 550°F/285°C. |

|||||||||||||||||||||||||||||||||||||||||||||||

EXCELLENT FOR COMPLEX MOLDED PARTSMiller-Stephenson release agents have proven themselves in the most complicated and demanding molded part configurations imaginable. The active ingredient is PTFE, or polytetrafluoroethylene, which has an extremely low coefficient of friction and, thus, imparts high lubricity and excellent nonstick properties. Distortion is virtually nonexistent - an extremely important criterion in precision molding. |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

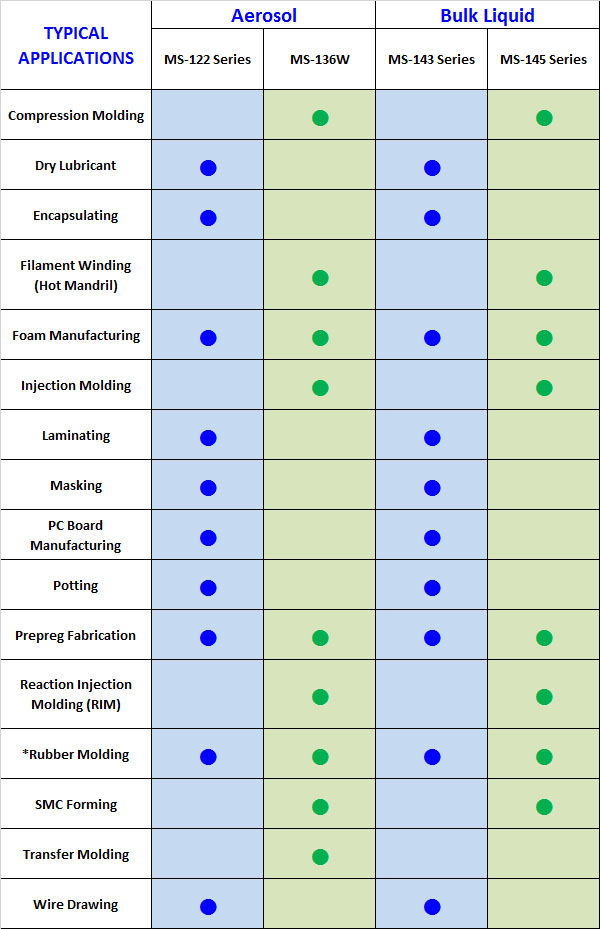

Process Selection ChartMiller-Stephenson release agents and dry lubricants are versatile and are used in a variety of products and manufacturing operations: |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

Application Selection Chart |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

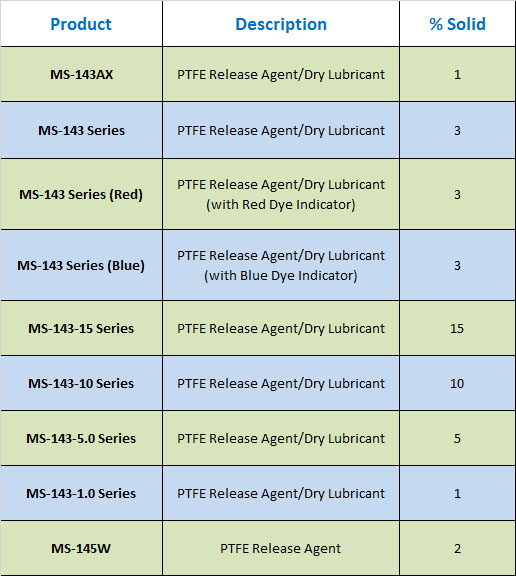

Bulk Liquid for Brush, Dip, and Spray Gun Application |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

Custom formulations available |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

Dry Lubricant Applications |

|||||||||||||||||||||||||||||||||||||||||||||||

The outstanding lubricity of the PTFE (polytetrafluoroethylene telomer) solids incorporated in Miller-Stephenson Dry Lubricants is indicated by the low coefficient of friction. The following values were determined at 23 pounds per square inch: steel on steel, 0.11; aluminum on aluminum, 0.16; hardwood on hardwood, 0.10. All Dry Lubricants, whether packaged in aerosol or bulk, may be applied to the following materials:

|

|||||||||||||||||||||||||||||||||||||||||||||||

Dry Lubricant Selection Chart |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

Miller-Stephenson’s Dry Lubricants minimize "slip-stick" problems, and are most effective in low speed, light load applications. Specific uses include:

|

|||||||||||||||||||||||||||||||||||||||||||||||

Release Agents / Dry Lubricants |

|||||||||||||||||||||||||||||||||||||||||||||||

MS-122 and MS-143 Series PTFE Release Agents/Dry Lubricants create superior releases for plastics, elastomers and resins; including acrylics, urethanes, rubber, nylons, epoxies, polycarbonates and polystyrene. Designed to give multiple releases between applications. Recommended for applications to 580°F (304°C).To increase number of releases between applications, coating may be fused at 581°F (305°C) to 590°F (310°C). Performance may vary due to mold temperatures and mold type. As a dry lubricant, may be used on metal, glass, ceramics, rubber, elastomers, wood, paper and some plastics. No discernible transfer. No migration. Nonflammable. Contains no silicones. No ODC (ozone depleting chemicals). To select the most suitable product for your application, please call our Technical Service Department (8 AM - 4 PM E.T.): 800.992.2424 or 203.743.4447. In Canada, call 800.323.4621. |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

To learn more about our latest copy of our Krytox® Catalog, please contact our Technical Service Department. USA: 1.800.992.2424 Canada: 1.800.323.4621 |

Copyright © 2015 Miller-Stephenson Chemical Company, Inc. All rights reserved.