XP lubricants are formulated using patented soluble additives. Typical perfluoropolyether (PFPE) greases use solid additives for antirust, anti-wear, or extreme pressure performance. These components are mixed into the grease and held in place by the grease thickener. In the past, there were no additives available for the oil, because of the inertness of the oil and insolubility of available additives.

The Krytox™ XP lubricant line offers greases and oils—with a soluble additive in the oil. The soluble additive won’t be washed away or left behind with the grease thickener. These patented additives enhance the performance of PFPE greases and oils, giving them improved performance properties. Bearings run quieter and wear less, because there are no solid additives to make noise. Lower wear will extend bearing and component life. The anticorrosion protection of the additive will reduce rusting and allow longer grease and bearing life. The extreme pressure properties of the additive protect bearings under high loads.

XP lubricants will hold up under tremendous load conditions, preventing metal-to-metal contact and thereby reducing wear. The long-term anti-rust properties repel moisture, providing extra protection against corrosion of metal parts and bearing surfaces.

They also exhibit excellent resistance to water washout when used in wet environments.

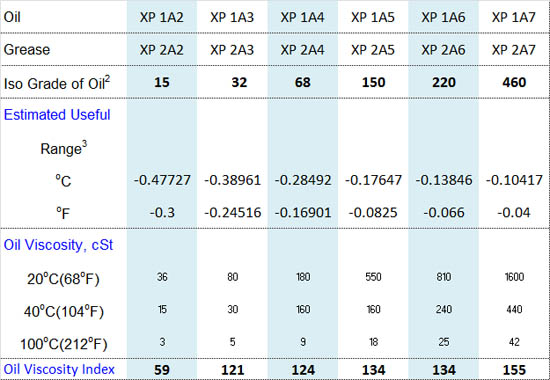

Typical Properties of XP Lubricants:

²Approximate

³Based on pour point and where evaporation is approximately 10%..

|