Fluoroguard™ Polymer Additive |

|||

Chemours™ Fluoroguard™ are multifunctional polymer additives based on fluorinated synthetic oil. They are perfluoropolyether (PFPE) and have excellent color, UV, and thermal stability. Added to plastics and elastomers, they improve processing of polymers. It internally lubricates to improve flow properties, processibility, throughput, uniform mixing/dispersion of ingredients, and offers many advantages over competitive process aids. Fluoroguard™ can be used in a variety of thermoplastic and thermosetting polymers at typically less than 1% (by weight) to improve mechanical performance of products and processing characteristics such as increasing wear and flex fatigue resistance and making parts last longer. There are three grades of Fluoroguard™: PCA: used for enhancing product performance, while also providing processing benefits. Benefits and Features

In addition to these advantages, it has also been observed that there is little or no change in initial and aged physical properties of polymer compounds containing Fluoroguard®. Compounding Fluoroguard™ can be incorporated into the polymer matrix by using conventional melt compounding equipment. Some grades can be processed at temperatures as high as 680°F (360°C) because of excellent thermal stability and low volatility. The recommended loading of Fluoroguard™ is 0.1-1.0%, depending on the base polymer matrix and final performance desired. To realize efficient Fluoroguard™ incorporation, a twin –screw extruder with liquid injection capability is most suitable for compounding this additive with thermoplastic polymers. For thermosetting polymers, a normal mixing procedure (internal mixer or other high shear mixer) can be followed. Typical applications include:

|

|||

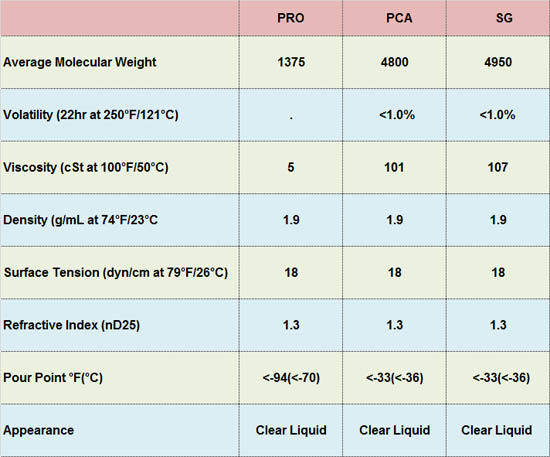

Typical Properties of Fluoroguard™ |

|||

| |||

|

|||

|

|||

To learn more about our latest formulations, please contact our Technical Service Department.USA:1.800.992.2424 Canada:1.800.323.4621 |

Copyright © 2015 Miller-Stephenson Chemical Company, Inc. All rights reserved.