Conformal Coating with the Technical Advantages of Aerosol Sprays

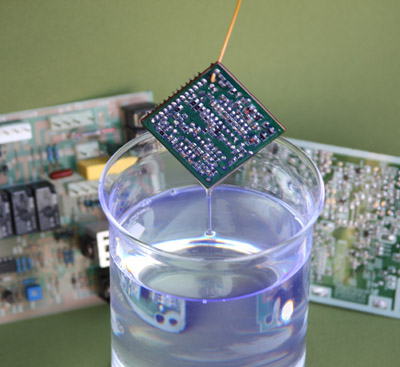

As protective coatings have become a more important part of electronic products, coating requirements have become more demanding. To meet these needs, Miller-Stephenson offers a choice of conformal coatings, each formulated to a specific requirement. Whether your specification calls for urethane, silicone, acrylic or varnish, we have the coating you need in easy application aerosol containers and bulk packages.

Miller-Stephenson aerosol coatings offer:

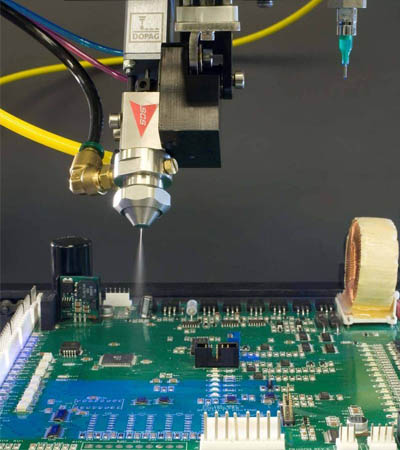

Uniformity:

Each aerosol container provides a premixed standardized coating with carefully controlled solids and solvent concentration. A two-coat spray applies a uniform coating of 2 mils, providing maximum protection while allowing ease of repair.

Ease of Application:

Fingertip control directs coating spray without waste. No setup or cleanup of spray equipment. Handy for bench top use and field repair kits.

Removability and Repair:

All Miller-Stephenson coatings are removable with MS-114C Conformal Coating Stripper. Coatings are easily "soldered through" for easy repair.

Quality Control:

All of our conformal coatings have an ultraviolet (UV) indicator for quality control inspection.

All of our coatings are clear for component identification, and provide excellent electrical insulation and moisture resistance.

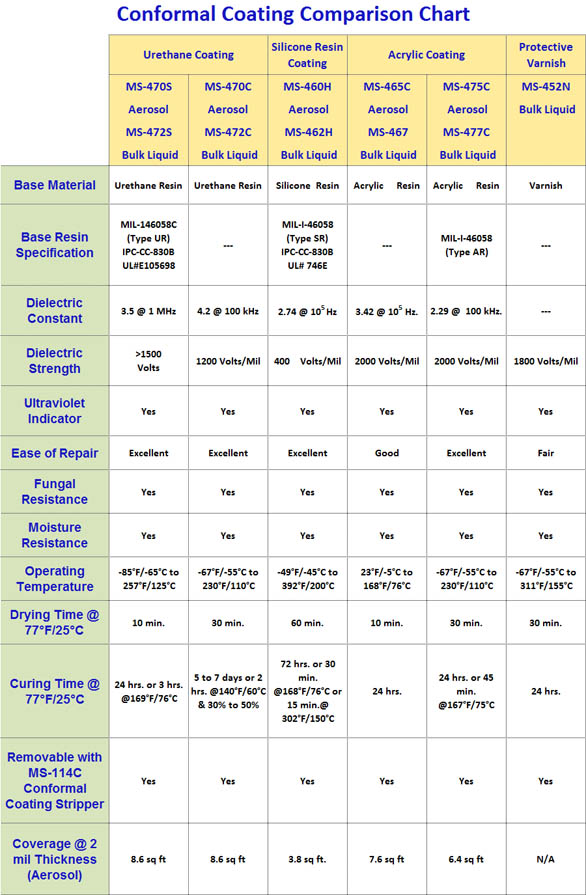

However, since the degree of electrical insulation, drying time, chemical resistance, weatherability, thermal shock resistance, durability and repairability vary among the coatings, we have provided you with a comparison chart.

Properly selected, the use of a conformal protective coating can improve the performance, life, reliability and safety of your product. Use the chart below as a guide in selecting the right coating for your application.

Special Properties:

MS-470S/MS-472S:

Superior toughness and abrasion resistance and excellent protection from humidity and organic solvents.

MS-470C/MS-472C:

Excellent chemical, moisture and fungal resistance with good dielectric properties. May be "soldered-through" for ease of repair. Moisture cured.

MS-460H/MS-462H:

Excellent moisture and fungal resistance and good dielectric properties. Soft and flexible coating. May be "soldered-through" for ease of repair and replacement of components.

MS-465C/MS-467C:

Tough, abrasion resistant, "soldered-through" coating. Excellent insulation against high voltage arcing and corona shorts. Fast drying. Protects against caustics and corrosives. Easily removed by solvents.

MS-475C/MS-477C:

Superior toughness and abrasion resistance. Provides excellent insulation and moisture resistance. May be "soldered-through" for ease of repair. Easily removed by solvents.

MS-452N:

Designed for adverse environmental conditions. Provides electrical insulation and moisture resistance to increase the reliability of printed circuit boards.